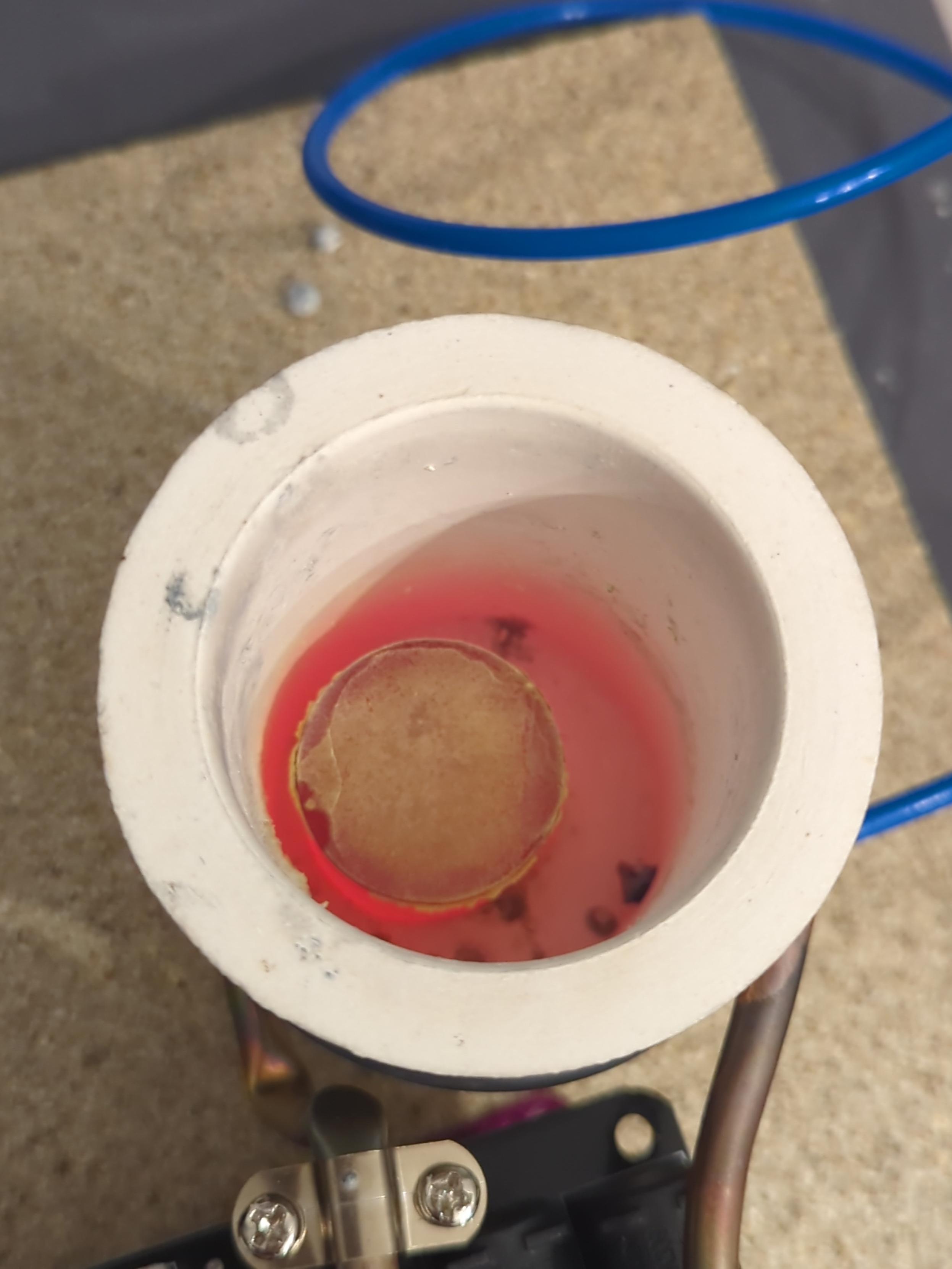

HELL YEAH operation "Magnesium" was a success

-

HELL YEAH operation "Magnesium" was a success

by feeding inert gas from the bottom i have avoided it setting itself on fire!!!

it's cooling down nicely

-

✧✦✶✷Catherine✷✶✦✧replied to ✧✦✶✷Catherine✷✶✦✧ last edited by

video

i think the reason it smokes is Mg vapor escaping into atmosphere

-

✧✦✶✷Catherine✷✶✦✧replied to ✧✦✶✷Catherine✷✶✦✧ last edited by

key points:

- dry every part of the apparatus that will be heated (crucible, reagents, enclosure) for 4h at 150 degC

- use lots of NaCl flux

- fill crucible with argon before closing it

- feed argon into the enclosure from the bottomthings to improve:

- mix NaCl flux with MgCl2 for improved wettability of the oxide

- cover the top of the enclosure to somewhat reduce the amount of escaping Mg vapor (as well as heat) with an alumina dish

- heat it for several minutes to ensure complete melting -

✧✦✶✷Catherine✷✶✦✧replied to ✧✦✶✷Catherine✷✶✦✧ last edited by

what i find really interesting is the relatively slow heat transfer from the graphite crucible to the magnesium. the crucible was glowing white hot, magnesium has a melting point of only 650°C, and yet it's barely melted

even their specific heat capacity is very close. i dunno why it's like this

-

Asta [AMP]replied to ✧✦✶✷Catherine✷✶✦✧ last edited by [email protected]

@[email protected] huh. both graphite and magnesium are good thermal conductors as well, right? could impurities burning out impact the heat transfer? Or possibly the argon (I think you said argon)?

Argon does seem to have low thermal conductivity; I haven’t followed the whole thread but maybe since you’re piping it in from the bottom and pre-filled the crucible, you’ve essentially “wrapped” a layer of argon in between the graphite and magnesium? That might impact the thermal transfer rate, right?

EDIT: oh, you said piping argon in to the bottom of the enclosure, not the crucible (which would be difficult anyway without splattering or… other… things). So nevermind on that.